Hydroelectric DC Charging

Use to charge a 12, 24 or 48 volt battery 24 hours a day either alone or with solar modules, wind generator or engine generator. A 100 gallons per minute of water falling 10 feet or 5 gallons per minute falling 200 feet through a pipe can generate 80 watts. This is about 1.9 KiloWatt hours a day and would equal about five 75 watt solar modules in a 5 peak sun hour location. A diversion type regulator and dump load is needed to prevent battery overcharging.

The amount of power available depends on the dynamic head, the amount of water flow and the efficiency of the hydroelectric unit.

Most micro hydroelectric turbines operate from the pressure at the bottom end of a pipeline. This pressure is measured in pounds per square inch (PSI) and is directly related to the head, or vertical distance from where the water goes into the pipe at the top of the pipeline, to the turbine located at the bottom of the pipeline.

You should know your Total Head, Flow rate in gallons per minute, Pipe length needed, Wiring distance from hydro unit to batteries.

Head in Feet times Flow in GPM divided by 10 will equal the approximate Watts available

|

|

Low Voltage Hydroelectric Generator Brushless Permanent Magnet Alternator with rectified DC output

400 to 1500 Maximum Watt Output |

|

|

|

|

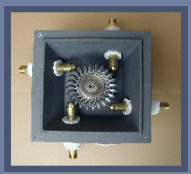

Older style with Harris housing and bronze Pelton runner |

||||

|

Stainless Steel Turgo |

||||

|

1 nozzle LV800

Hydro Turbine W522 60 lbs

$1600 2 nozzle LV800 Hydro Turbine W523 60 lbs $1650 3 nozzle LV800 Hydro Turbine W524 60 lbs $1700 4 nozzle LV800 Hydro Turbine W525 60 lbs $1750 1 nozzle LV400 Hydro Turbine W530 60 lbs $1600 2 nozzle LV400 Hydro Turbine W531 60 lbs $1650 3 nozzle LV400 Hydro Turbine W532 60 lbs $1700 4 nozzle LV400 Hydro Turbine W533 60 lbs $1750 1 nozzle LV1500 Hydro Turbine W534 60 lbs $2100 2 nozzle LV1500 Hydro Turbine W535 60 lbs $2150 3 nozzle LV1500 Hydro Turbine W536 60 lbs $2200 4 nozzle LV1500 Hydro Turbine W537 60 lbs $2250 1 nozzle LV750 Hydro Turbine W538 60 lbs $2100 2 nozzle LV750 Hydro Turbine W539 60 lbs $2150 3 nozzle LV750 Hydro Turbine W540 60 lbs $2200 4 nozzle LV750 Hydro Turbine W541 60 lbs $2250

Specify voltage 12V, 24V, 48V, or 120V |

LV800 |

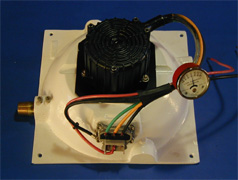

These units use a cast aluminum housing and now have a stainless steel turgo

runner. This turgo is slightly more efficient and is longer lasting than the

bronze pelton runner. All hardware is stainless steel, and nozzle

holders and nozzles are brass. Units will work on pressures from 20psi to 180psi.The alternator is a brushless permanent magnet, 12 pole, with 2 x 6203 sealed bearings. These commonly available bearings should be changed every 4 - 10 years, depending on use. The alternating current from the alternator goes through the water-cooled rectifier to produce DC for your battery. The unit comes complete with an induction amp meter and 1'' flexible hose for easy hook-up. We recommend fusing the wire near the batteries. Units have a 2 year factory warranty. A diversion type regulator and dump load is needed to prevent battery overcharging. |

||

|

Harris Hydro Pelton Turbines |

||

|

12 - 24 - 48 volt models with 1 nozzle W512 70

lbs

$2195 |

Head Range is 20’ to 600’,

Flow Range is 4 to 250 GPM PM Alternator 1000 watt. This turbine uses a cast bronze pelton wheel, aluminum housing and a Permanent Magnet, brushless alternator for better efficiency, less maintenance and long life. A diversion type regulator and dump load is needed to prevent battery overcharging. |

|

|

Make your own hydro turbine with these runners. Bronze Turgo Runner Has 4” pitch diameter (the place where the center of the water jet is aimed). For up to 1” nozzle. Fits Ford or Delco alternator, has 5/8” threaded hole. W519 10 lbs $825 |

|

|

Stainless Steel Turgo Runner This is the same runner as used on the Low Voltage

Hydroelectric Generator. Hydraulic pitch diameter is 4". Runner is

5-1/2" outside diameter, 1-1/16" thick. Mounting hole is 17mm

threaded. It is more durable and longer lasting than Bronze.

For up to 1"nozzle. W526 5 lbs

$450 |

|

|

Harris Silicon Bronze Pelton Runner Fits GM and Ford Shaft, 5” diameter, 4” hydraulic

diameter, 85-90% efficient, for up to 1/2" nozzle. |

POWER OUTPUT & SITE ASSESSMENT

To determine the power available at a site, head and flow measurements must be taken. Flow is the rate at which water moves, measured in liters per second (l/s) or gallons per minute (gpm). This can be measured by channeling the water into a pipeline, then into a container of a known volume, noting the time it takes to do so. A weir can be used to measure flows in larger streams. Head can be measured by using a transit, by looking along a level, or by using a pressure gauge at the end of the pipeline. An altimeter can also be used, so long as it is accurate, and sufficiently sensitive.

It is important to keep in mind that output can only be accurately determined if head and flow measurements are made correctly, so care should be taken during this process. Two other important factors in a site assessment are system voltage, and transmission distance. The voltage and distance the power must travel can affect the efficiency and cost of your transmission lines.